Process Diagnosis

- Categories:企业医院

- Time of issue:2021-05-07 13:55:30

- Views:0

1. Process diagnosing

Screening and evaluation criteria of routing

l Safety and environmental protection

l Have comparative advantages of economy and technology ( low investment and cost)

l Raw material and solvent are easy to obtain and meet the needs

l Raw material and solvent prefer to be non-toxic, low-toxic and environment friendly

l Raw material would better be natural or renewable resources

l Solvent would better be water or other safe and cheap substances

l Steady process, easy to control, little influence on changing conditions

l low energy and material consumption and high input-output ratio

l form a chain of industries of product and waste taking advantages of each other

l Have strength of using nearby resource or logistics

Basic requirements of process optimization

l To achieve clean and safe production

l To realize upsizing, continuous and automation production

l To improve atom utilization (green process)

l To get highest yield

l To promote content and quality

l To reduce energy and material consumption

l To increase capacity

l To decrease manual labour

l To cut down investment

l To elevate industry state and market share

Principles and steps of process optimization

l 4 basic rules of process optimization

l Firstly repeat existing process

l Build proper analyze and control method

l Only changing one condition one time during optimization (orthogonal experiment)

l Pay attention to 80/20 rule

l Three principles

l Form summary sheet of process optimization experiment of reaction process

First class design concept design, pilot device design, basic design

Concept design is one segment of engineering research. It is a hypothetical design according to future industrial production device when applied research develops to a certain stage. Work content is to determine process, condition, major equipment’s form and material and three wastes treatment, which is based on concept and data of research. After that main techno-economic indexes as capital investment and product cost are confirmed. Concept design is combination of design and research at early stage and it is a combination of General engineering experience and research object’s character. It is contribute to find problems and solve problems in time. Development period is also shortened.

Pilot design.

Certain development project could not be magnified by method of mathematical model. Some research subjects couldn’t achieve in lab test and should acquire the experimental data by comparable scale of device. Both of conditions require pilot scale experiments. Pilot scale experiments are designed to verify discipline obtained by basic research, inspect amplification effect from lab scale to pilot scale and research several project that have no access to do in lab experiment with new device, material, equipment and control plan.

Pilot plant’s design don’t require identical with industrial plant in process and structure of equipment. But it should reflect character and rule of industrial plant and obtain all the data that basic design required, which could make industrial plant have non-estimated problem whengo into operation. Pilot plant design’s content basically the same as engineering design. But the scale is smaller. If construction installation is high force, pipe, instrument and pipe support’s installation drawing are not essential.

Basic design procedure(Class 1)

Basic design--- process pack. Basic design is a complete technical software and it is the result of research in the whole technical evaluation stage. It should be proceed after research content accomplished and appraisal. Basic design content include production plant’s all technical essentials. Qualified engineers based on basic design could accomplish a production plants that could go into operation and get certain output and quality index. Basic design should specify the industrial process, main process characteristics and provide reaction principles, process parameters, operating conditions, pipeline process and control plan. They should also request grade of special pipe and nominal diameter. They need to determine main control plan’s principle, standards of control, control points’ database, main instrument selection and special instrument’s technical condition. They show the the defining of dangerous areas of plants and list the material being handled characteristic and admissible concentration and special measures of safety production, accident management and labor protection.

Engineering design procedure (Class 2)

established international division of design phases include process design, basic engineering or analytical and planning engineering, detailed engineering or final design. Each stage’s basic function and content as follow.

|

|

Licenser |

Engineering Corporation |

||

|

|

Process Package Basic Design |

Process Design |

Basic Engineering or Analytical and Planning Engineering |

Detailed Engineering or Final Design |

|

Leading Discipline |

Process |

Process |

System/ Pipe |

|

|

|

1.PFD 2.PCD 3.process specification 4.process equipment list 5.design data 6.rough arrangement |

1.PFD 2.PCD 3.process specification 4.balance sheet of materials 5..process equipment list 6.process data table 7. security memorandum 8.rough arrangement 9.each specialized design condition |

1.PID 2.equipment design and sketch analysis 3.design specification 4.material selection 5.requisition 6.equipment layout( partition) 7.piping arrangement( partition) 8.underground pipeline network map 9.electric single line diagram

|

1. detailed piping diagram 2. isometric drawing 3. foundation drawing 4. structure chart 5. instrument design drawing 6. electrical lay-out drawing 7.equipment manufacture drawing 8. Other related drawing and document |

|

Function |

Provide engineering corporation as a design basis and it is technical assurance foundation |

Convert licenser’s document to engineering corporation’s design document. Send them related professions to carry out design work and provide customer’s evaluation |

Provide the whole materials for detailed engineering design and offer requisition about equipment and material procurement |

Provide detailed diagram and document required during construction. It is also basis for construction and booking of material supplement |

Design procedure

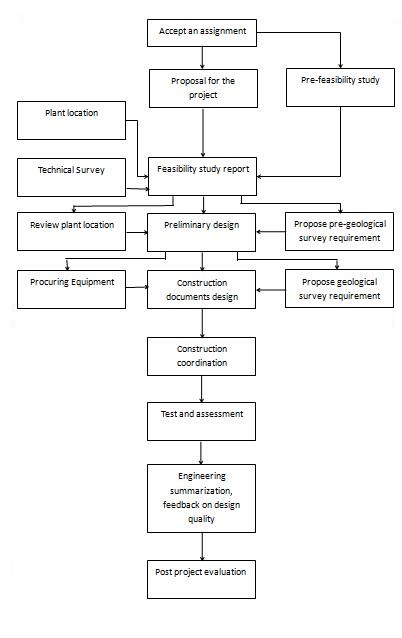

Accept a commission and work out a proposal for the project. Choose plant location and draw up plant location report. Do technical investigation and compile pre-feasibility study report and feasibility study report. Review plant location and raise geological survey requirement of plant location. Start preliminary design and purchase of equipment and main material. Propose detailed geological survey requirement. Develop construction drawing design. Manage the operating spot. Participate in test , assessment and completed acceptance. Develop engineering summarization, feedback on design quality and post project evaluation.

The difference between proposal for the projects and feasibility study report

Proposal for the project content include the background, purpose and significance project construction, market preliminary prediction and analysis, production solution and scale, process technology primary plan, supply of raw material, fuel and power, site construction condition and site ‘s preliminary plan, preliminary scheme of utility and supporting facility, environment protection, factory organization and manpower quota estimation, project Implementation’s preliminary planning, investment estimate and financing program, preliminary evaluation of economic benefit and social benefit.

Feasibility study report content include the background, purpose and meaning of project construction, market forecast, production solution and scale, process technology plan, the supply of raw material, auxiliary material and fuel, site construction condition and site plan, utility and supporting facility plan, energy conservation, environment protection, labor protection and safety and sanitation, factory organization and manpower quota estimation, execution planning for construction project, investment estimate and financing program, finance, economy evaluation and evaluation of social benefits and risk analysis.

They are two different stages of investment project’s preliminary work. The differences reflect in service function, research emphasis, structure contents and depth requirement. proposal for the project focus on necessity to analyze and research. Feasibility study report emphasize feasibility to do analytical investigation, if necessary, it is further proved the necessity of project.

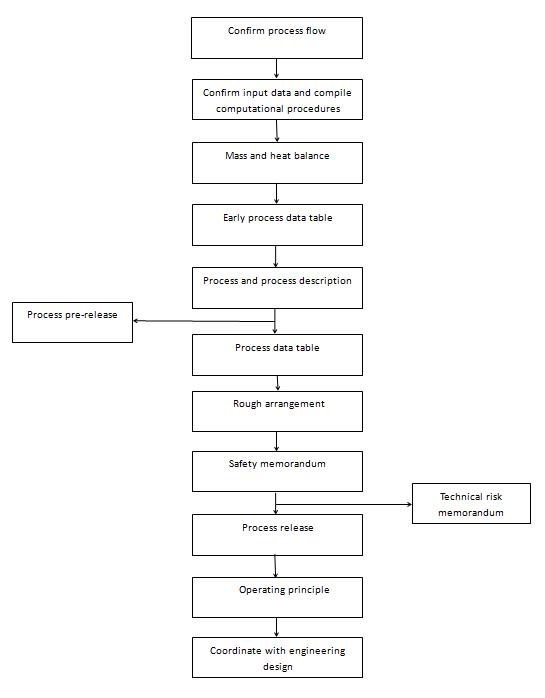

Main content of process design

Process flow diagram, mass balance diagram, process specification, process data table, process equipment table, rough arrangement, safety memorandum, technical risk memorandum and operating principle.

Licenser provide process package: process design is mainly to investigate and assess licenser’s process package. Convert licenser’s process package into engineering corporation’s design document and release to related profession to develop engineering design.

whole production route of process development project: the project should have process of the lab test, conceptual design, pilot design and industrial equipment design.

R&D department provide pilot or lab test data: when R&D department provide pilot or lab test data as process design condition, the times of process pre-release in process design procedure should be increased. And it should be formally released after the repeated discusses modification.

Standard: process design refer to SINOPEC design standard “ petrochemical plant process design package ( Packages of process technology )” (Standard No. SHSG一052—2003)

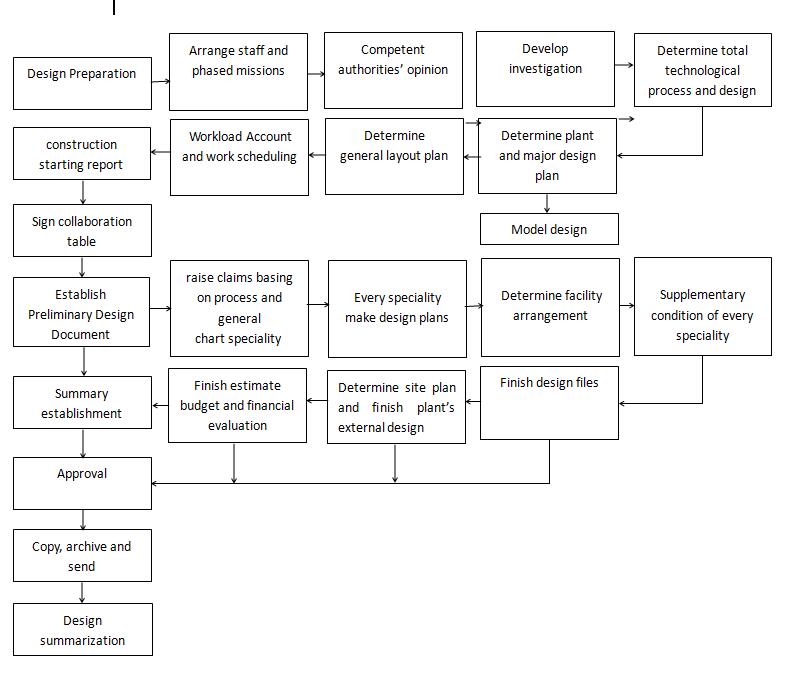

Main foundation of prepare preliminary design

Approved construction project’s design specification ( feasibility study report) and approval.

Overall design and approval (when exist) and contract name and number of introduction of foreign talents (when exist)

Design contract signed with owner (Construction unit)

Meeting summary of design condition held with owner (Construction unit)

Government approval documents in firefighting, environment protection, safety, occupational health and so on.

Owner (Construction unit) provide raw material, utilities supply report and other related documents and protocols required to carry on project.

The new process, technology, equipment and material in design which need provide trial report and technical appraisal.

Beijing Insight Ecological Technology Co., Ltd.

Address: East Road, Haidian District, Beijing Anningzhuang 18 Tell:010-62944395 Mail:insight@insight.net.cn

《People's Republic of China telecommunications and information services business license》Numbering:京ICP备19053360号-1 Powered by www.300.cn